Thông tin chi tiết

Hydraulic cylinders are essential components in hydraulic systems, used to generate force and motion through hydraulic fluid pressure. Designed for high performance and durability, they can operate at a maximum working pressure of up to 200 bar and a testing pressure of 300 bar. With a maximum working speed of 0.5 m/s, they ensure efficient operations in heavy industrial applications. The cylinders are built to withstand extreme conditions, functioning in temperatures ranging from -30 ºC to +90 ºC, and use mineral hydraulic oil for optimal performance. Hydraulic cylinders are the ideal solution for applications requiring powerful thrust and high precision.

CHARACTERISTICS Hydraulic cylinder

-

Maximum working pressure: 200 bar

-

Maximum testing pressure: 300 bar

-

Maximum working speed: 0.5 m/s

-

Working temperature: -30 ºC to +90 ºC.

-

Oil: mineral hydraulic.

MATERIALS Hydraulic cylinder

- Rod: chrome plated steel F-1140, minimum chrome layer thickness 20 micron, roughness Ra < 0,2, minimum surface hardness 900 HV, corrosion resistance minimum 200 hours in neutral saline fog according to ISO9227 rating 9.

-

Tube: steel ST-52-3, DIN 2393, inside diameter tolerance ISO H9, roughness Ra <0,8 micron.

-

Guide-bushing: steel F-1140 nitrited (nitride hardening)

-

Piston: steel F-1140.

SEALS For Hydraulic cylinder.

– Guide-bushing:

-

Dynamic: compact polyurethane rod-seal, double lip. NBR metal wiper seal.

-

Static: NBR 90 shore o-ring.

– Piston:

-

Dynamic: compact double-acting polyurethane seal, plus nitrile o-ring as activator. Special polyacetal guides reinforced with glass fiber.

-

Static: polyamide locking sealing guide.

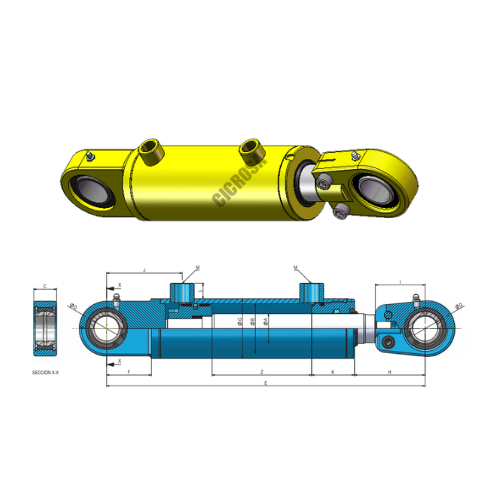

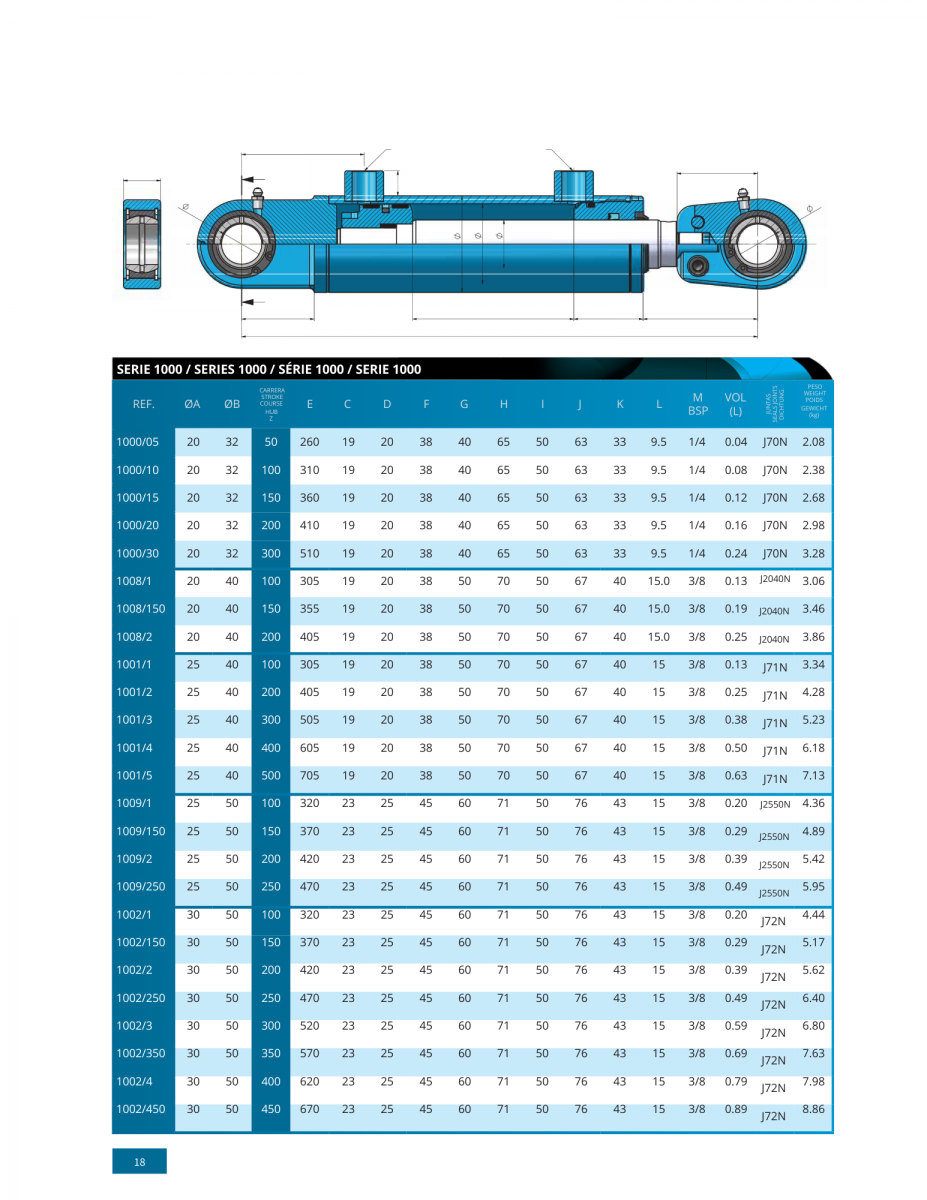

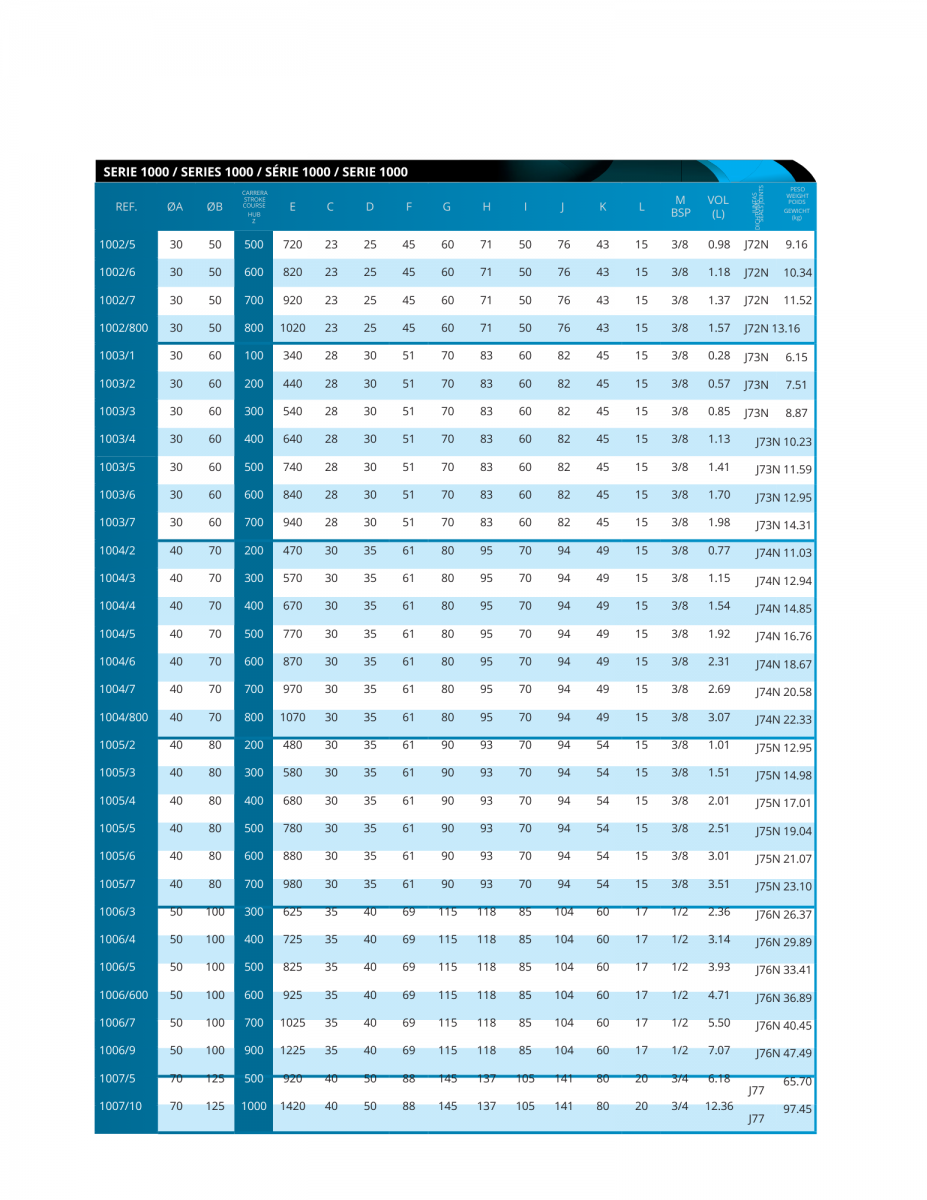

Double Acting Hydraulic Cylinders